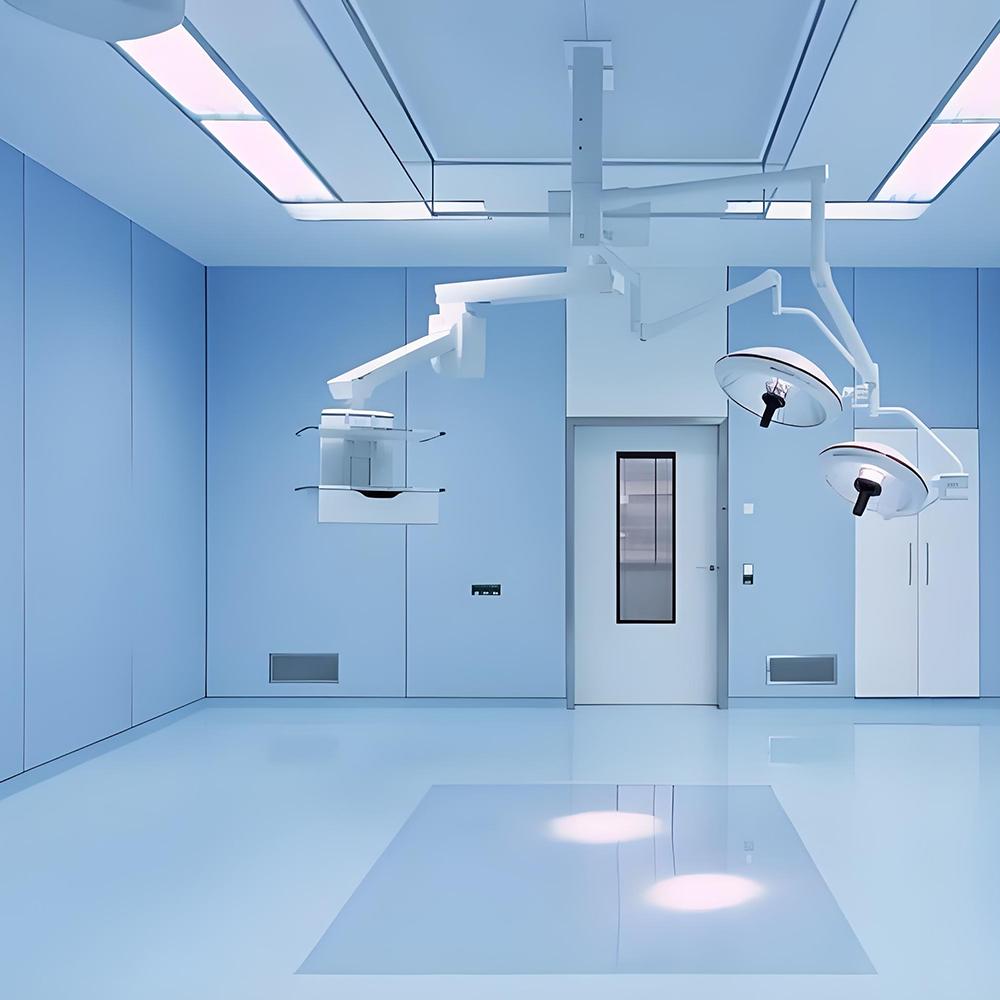

Application of air purifiers in dust-free workshops

With the continuous development of science and technology and the promotion of industrial automation, more and more industries need to carry out production and research and development in dust-free workshops (clean rooms). Dust-free workshops provide a controlled environment to reduce the impact of dust, pollutants and microorganisms on product quality. In such an environment, the application of air purifiers is particularly important. Let's discuss the necessity, types, and how to choose and maintain the effectiveness of air purifiers in dust-free workshops.

Characteristics of dust-free workshops

Dust-free workshops are commonly used in high-tech industries such as semiconductors, pharmaceuticals, biotechnology, optics, aerospace, etc. Its main features include:

Air cleanliness level: Dust-free workshops are divided according to air cleanliness levels, such as ISO 1 to ISO 9. The higher the level, the less particulate matter is allowed.

Temperature and humidity control: Maintain stable temperature and humidity to avoid affecting the production process and product quality.

Strict management of personnel and items in and out: prevent external pollutants from entering.

Necessity of air purifiers

In dust-free workshops, the main function of air purifiers is to remove pollutants such as tiny particles, volatile organic compounds (VOCs), bacteria and viruses in the air. Here are some of the reasons why it is necessary:

Improve air quality: Efficient air purifiers can continuously monitor and filter pollutants in the air to ensure that indoor air quality meets the specified standards.

Protect product quality: In industries such as microelectronics and pharmaceuticals, products are extremely sensitive to pollutants. Using air purifiers can significantly reduce the defective rate and improve the product qualification rate.

Protect employee health: A clean air environment helps reduce employee health problems caused by poor air quality and improve work efficiency.

Types of air purifiers

According to different purification needs, air purifiers can be divided into several types:

HEPA filter: High-efficiency particulate air (HEPA) filters can capture at least 99.97% of particles with a diameter of 0.3 microns and are widely used in dust-free workshops.

Activated carbon filter: Mainly used to adsorb volatile organic compounds (VOCs) and odors in the air, often used in conjunction with HEPA filters.

UV-C light cleaning equipment: Use ultraviolet light to kill bacteria and viruses in the air and provide secondary protection for the environment.

Negative ion generator: Promotes air purification by releasing negative ions, but be cautious when using it in a dust-free workshop to avoid secondary pollution.

How to choose an air purifier

When choosing an air purifier, you need to consider the following factors:

Purification efficiency: Check the product's CADR (clean air delivery rate) and filtration efficiency to ensure that it can meet the standards required by the dust-free workshop.

Applicable area: The applicable area of the purifier should match the actual area of the dust-free workshop to ensure that the entire environment is covered.

Maintenance cost: Regular replacement of filter elements, cleaning and other maintenance links need to be taken into account to reduce long-term operating costs.

Noise level: Since the dust-free workshop has high requirements for the environment, it is more appropriate to choose a low-noise purifier.

Maintain the effectiveness of the air purifier

In order to ensure that the air purifier can operate effectively in the dust-free workshop for a long time, managers should regularly perform the following maintenance:

Regular replacement of filter elements: According to the frequency of use and the type of filter element, a replacement plan should be formulated to prevent the filter element from being saturated and causing a decrease in effect.

Regular cleaning of equipment: Keep the outside of the purifier clean to prevent dust accumulation from affecting the internal circulation.

Monitoring air quality: Use air quality monitoring instruments to monitor the air conditions in and out of the dust-free workshop in real time, so as to facilitate timely adjustment of the working status.

Regularly train staff: ensure that operators are familiar with the use and maintenance procedures of the equipment to improve overall operating efficiency.

The application of air purifiers in dust-free workshops is an important part of ensuring product quality and employee health. By selecting appropriate equipment and strengthening maintenance management, the air quality of dust-free workshops can be effectively improved, creating an ideal environment for the production and research and development of high-tech products. In the future industrial development, air purification technology will continue to play a more important role.