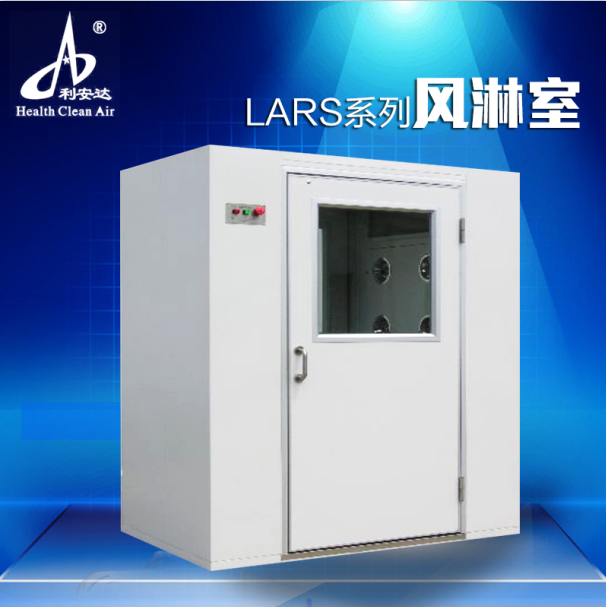

The wind shower room, also known as the "wind bath room", is an essential facility at the entrance of every clean workshop or factory. Its main function is to remove dust and small impurities from the staff. Before entering the clean area, workers need to undergo strong purification in the air shower room. The clean air blown out by the nozzles around the equipment comprehensively cleans the human body from all directions, quickly removing dust, hair and other debris from clothing.

More importantly, the shower room has two doors that achieve electronic interlocking function, which can effectively prevent external pollution and impure air from entering the clean area, ensuring the cleanliness of the internal environment of the workshop. This not only ensures product quality, but also reduces cleanroom pollution caused by personnel flow. Simply put, it is an efficient air purification door that ensures the air quality inside the clean workshop and ensures the production of high-quality products.

The delivery window, also known as the delivery window, is mainly designed to transfer objects between clean rooms and non clean rooms, with the aim of reducing the number of clean room door openings and effectively avoiding cross contamination between clean rooms and non clean rooms. Generally, transfer windows are designed with a double door interlock system, which means that when one door is opened, the other door is locked to prevent contamination caused by both doors being opened simultaneously.

Depending on the material, there are stainless steel transfer windows, steel plates on the outside and stainless steel transfer windows on the inside. In addition, it can also be equipped with sterilization lamps (8W) and walkie talkies and other equipment to increase convenience and safety of use. Simply put, it is a purification device that controls the transfer of items, effectively separating clean and non clean areas, and ensuring the stability of a clean environment.

The wind shower transfer window is a supporting facility in the clean room, mainly used to reduce the dust carried by goods during entry and exit. In this type of device, the clean airflow filtered by high-efficiency filters will be blown onto the goods from all directions through a rotating nozzle, quickly and effectively removing dust. The cleaned dust will be filtered through a primary and high-efficiency filter before being sent back to the air shower area. To achieve better shower effect, the wind speed of the nozzle should be maintained at least 20 seconds.

When it comes to the types of wind shower transfer windows, the first ones are vertical and floor standing; Furthermore, depending on the material, there are stainless steel shower transfer windows, shower transfer windows with steel plates on the outside and stainless steel on the inside, and so on; Later, according to the locking method, the electronic interlocking air shower transfer window and the mechanical interlocking air shower transfer window are divided. Simply put, it is an efficient purification device used to maintain clean isolation between indoor and outdoor spaces.

FFU Fan Filter Unit NO.4, which stands for Fan Filter Unit, is characterized by its modular connection and includes two levels of primary and high efficiency filters. During work, the fan draws in air from the top of the FFU, and after being processed by these two layers of filters, clean air is evenly blown out from the outlet surface at a speed of 0.45m/s.

This FFU fan filtration unit is designed to be lightweight, suitable for various Grid systems, and can also adjust the structural dimensions according to the Grid system. There is a diffusion plate inside to ensure uniform air pressure and stable air output. The overall structure is made of metal, durable and resistant to secondary pollution. Smooth surface, low wind resistance, and good sound insulation effect. Unique air inlet design reduces noise and pressure loss.

The motor of FFU has high efficiency, low current consumption, and is energy-saving and environmentally friendly. There are three stages of speed regulation, which can adjust the wind speed and air volume according to the actual situation. Strong adaptability, can be used alone or in series with multiple machines, suitable for clean spaces such as electronics, optics, and laboratories. It can be assembled into various sizes of clean work sheds using supporting structural components, especially suitable for the construction of small clean areas, saving time and cost.

The laminar flow hood mainly consists of a box, a fan, a high-efficiency air filter, a coarse efficiency filter, a porous plate, a controller, etc. The outer shell can be made of cold plate spray or stainless steel plate. It can filter the air through a high-efficiency filter to form a uniform flow layer, ensuring high cleanliness requirements in the working area. It is an air purification unit that can provide a local clean environment and can be flexibly installed above process points that require high cleanliness. The laminar flow hood can be used alone or combined into a strip clean area. It can be suspended and supported on the ground, with a compact structure and convenient use.

The performance characteristics of laminar flow hood include:

The purification level is static level 100, and the particle size of dust in the working area is ≥ 0.5m and ≤ 3.5 particles/liter;

The average wind speed is 0.3-0.5m/s, the noise is ≤ 64dB, and the power supply is 220V, 50Hz;

Adopting high-efficiency filters without partitions, with a filtration efficiency of 99.99%, ensuring purification level;

Made entirely of high-quality cold plate baking paint, aluminum or stainless steel plates;

The control methods include stepless speed regulation design or electronic board speed regulation, with stable speed regulation, ensuring that the air volume remains unchanged even in the final resistance state of the high-efficiency filter;

Adopting high-efficiency centrifugal fans, with long service life, low noise, maintenance free, and low vibration;

Specially suitable for assembling into ultra clean production lines, it can be arranged as a single unit for use according to process requirements, or multiple units can be combined into a 100 level assembly line.

A clean workbench, divided into vertical flow and horizontal flow, is an essential purification equipment in a clean working environment. Widely used in laboratories, biopharmaceuticals, hospitals, LED optoelectronics, circuit boards, microelectronics, hard disk manufacturing, food processing and other occasions that require high cleanliness.

The characteristics of a clean workbench are as follows:

Adopting ultra-thin non partition filters, the filtration efficiency reaches static level 100.

The medical workbench is equipped with an efficient centrifugal fan, which has a long service life, low noise, maintenance free, and low vibration.

The ultra clean workbench is equipped with an adjustable air supply system, and the wind speed can be adjusted steplessly through a knob, equipped with LED control switches.

The purification workbench is equipped with a large air volume coarse efficiency filter, which is easy to disassemble and helps protect the high-efficiency filter, ensuring cleanliness.

The static level 100 workbench can be used alone or combined into a level 100 ultra clean production line according to process requirements.

The clean workbench can be equipped with a pressure differential gauge, which clearly displays the pressure difference on both sides of the high-efficiency filter, making it easy to replace the filter.

The ultra clean workbench has multiple specifications and can be customized according to specific production needs.

Efficient air supply outlet, including static pressure box, diffuser, high-efficiency filter and flange, can be connected to the air duct in two ways: side or top connection. The surface of the box is made of cold rolled steel plate, and the air flow at the air outlet is uniform to ensure the purification effect. The high-efficiency air supply outlet is a 1000-30000 level cleanroom terminal air filtration equipment that meets purification requirements. Optional features:

Side or top air supply can be selected, and flanges can be square or circular.

The static pressure box can be made of different materials.

The flange can be square or circular, making it convenient to connect the air duct.

Diffuser plates can be made of different materials.

High efficiency filters can be selected with or without partitions.

Optional accessories: insulation layer, manual air volume control valve, insulation cotton, DOP testing.